Tips From PLC Automation Experts on How to Extend the LifeSpan of Your Automation Parts

- by PLC

- May 22, 2023

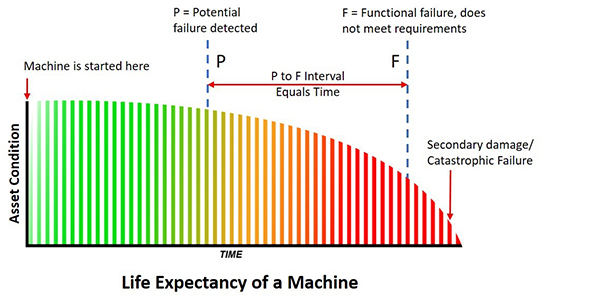

To maximise efficiency and cut expenses in the area of automation, it's essential to preserve the equipment's longevity. Breakdowns, more downtime, and frequent replacements can result from regular wear and tear. However, you can increase the lifespan of your automation parts and guarantee peak performance by adhering to a few straightforward measures. This blog post will look at practical methods for extending the life of your equipment so you may save time and money in the long term.

A simple Graph can Explain everything.

Regular Maintenance:

The key to preventing premature wear and damage to your automation parts is routine maintenance. Make a thorough maintenance routine, and follow it religiously. Cleaning, lubrication, calibration, and inspection of crucial components should all be on this timetable. You can save maintenance costs and increase the lifespan of your equipment by spotting and fixing possible problems early on.

Proper Lubrication:

In order to reduce friction and stop wear between moving components, lubrication is essential. To choose the proper lubricants and intervals for application, see the manufacturer's instructions. Strike a balance by adhering to suggested standards because overlubrication may be just as harmful as underlubrication. To guarantee optimum performance, keep an eye on the lubricant levels frequently and top them off as necessary.

Dust and Debris Control:

On automation parts, dust, filth, and debris can collect and negatively impact their performance. Put controls in place to limit and regulate the presence of pollutants at work. Keep the surrounding spaces clean on a regular basis, and apply air filters or dust coverings as needed. To further prevent the infiltration of pollutants into your equipment, think about adding air purifiers or maintaining a positive air pressure environment.

Temperature and Humidity Control:

High humidity and extreme temperatures can harm automation components, resulting in early failure. Make sure that your equipment runs within the manufacturer-recommended temperature and humidity ranges. Install dehumidifiers or temperature control devices if necessary to maintain ideal conditions. Monitor and record temperature and humidity levels on a regular basis to spot any abnormalities and act quickly to fix them.

Proper Training and Handling:

To prevent unneeded stress and damage, proper training of workers who use automation equipment is essential. Make sure that your crew is properly educated in handling methods, such as safe operating procedures, effective shutdown protocols, and loading/unloading processes. To stop additional harm, encourage staff to report any irregularities or indications of equipment malfunction.

Upgrade and Replace Outdated Parts:

Older automation components may become less effective and more prone to failure as technology develops quickly. Assess your equipment on a regular basis to spot any parts that are outdated or reaching the end of their useful lives. Upgrade these components to more recent, dependable models. You can improve the performance and increase the lifespan of your automation equipment by keeping up with the most recent technological developments.

Conclusion:

You may dramatically increase the lifespan of your equipment by adhering to these crucial recommendations for extending the life of your automation parts. Maximising the lifetime and effectiveness of your automation system requires regular maintenance, appropriate lubrication, dust and debris management, temperature and humidity control, adequate training and handling, as well as periodic upgrades. Remember that putting time and effort into preventative measures now will pay off in the long run by decreasing downtime and saving money. We at PLC Automation PTE LTD understand the need of the hour and with the best and the dedicated team we are the leading reseller of all sorts of obsolete parts where we aim to minimise the downtime from 24 Hours to maximum of 14 Days and with 12 months warranty.