Free Preventive Maintenance Planner Excel (PM & PdM) PLC Automation

- by PLC Automation

- Jan 10, 2026

Introduction

Unplanned equipment failures cause downtime, production loss, and high repair costs. A structured Preventive Maintenance (PM) plan is essential for industrial reliability — but many companies delay PM because of expensive CMMS software.

At PLC Automation, we’ve created a free PM & PdM Excel planner that helps you plan, schedule, and track maintenance activities without any software cost.

What Is a Preventive Maintenance Planner?

A Preventive Maintenance Planner is a structured schedule that ensures equipment is serviced before failures occur.

Our Excel-based PM & PdM planner allows you to:

- Plan maintenance by date

- Track completed PM activities

- Record Predictive Maintenance observations

- Maintain a full-year maintenance overview

Step 1: List Equipment & Maintenance Tasks

Start by identifying all equipment that requires maintenance:

- Motors

- PLC panels

- Drives

- Compressors

- Production machines

Each row in the planner represents one maintenance task, ensuring no asset is missed.

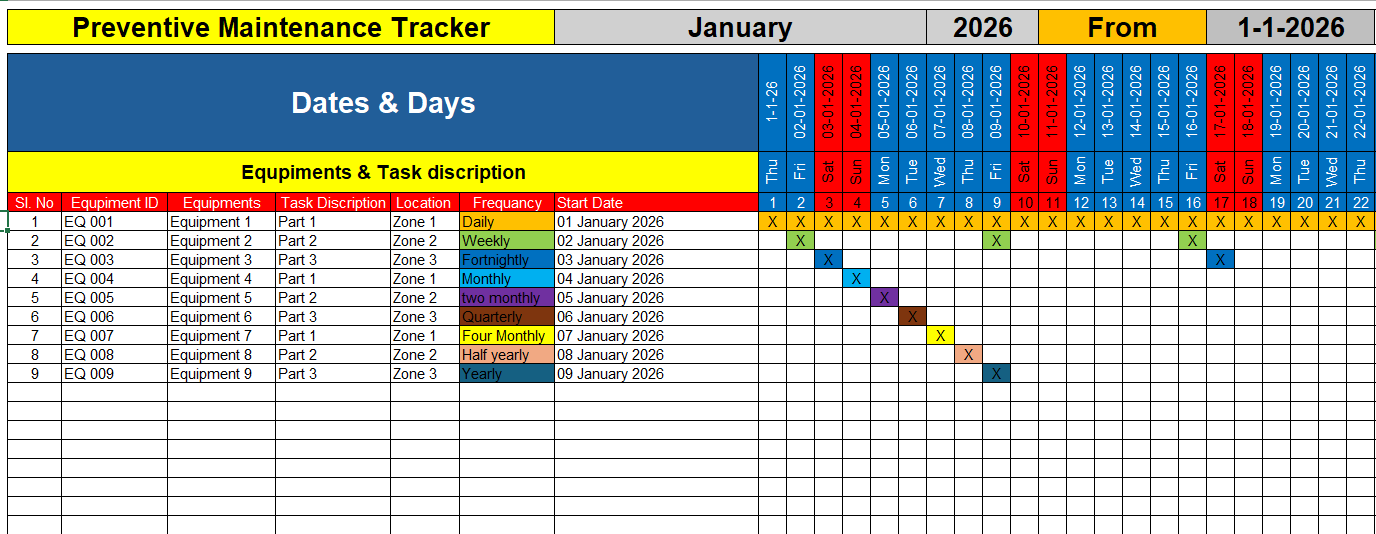

Step 2: Define Maintenance Frequency

The planner supports:

- Daily

- Weekly

- Monthly

- Quarterly

- Yearly maintenance

This allows easy scheduling based on manufacturer recommendations or site experience.

Step 3: Calendar-Based Maintenance Planning

The Excel planner uses a full calendar layout:

- Dates and weekdays clearly shown

- Tasks marked directly on scheduled days

- Overdue maintenance easily identified

This visual approach simplifies maintenance planning for technicians and supervisors.

Step 4: Track Preventive & Predictive Maintenance

Preventive Maintenance (PM):

- Inspection

- Cleaning

- Lubrication

- Functional checks

Predictive Maintenance (PdM):

- Condition checks

- Temperature observation

- Vibration notes

- Abnormal findings

All activities are recorded in one place.

Step 5: Build Maintenance History

Over time, the planner automatically builds:

- Maintenance history

- Frequency trends

- Repeating issues

This helps improve maintenance strategies and reduce failures.

Why Use PLC Automation’s Free PM Excel Planner?

- ✔ Free to use

- ✔ No CMMS software required

- ✔ Easy to customize

- ✔ Ideal for factories & automation systems

- ✔ Suitable for PM & PdM planning

Conclusion

Preventive Maintenance doesn’t need to be complex or expensive. With PLC Automation’s free PM & PdM Excel planner, you can start organizing maintenance immediately and reduce downtime effectively.

Download Landing Page (High Conversion)

Free Preventive Maintenance Planner Excel | PLC Automation

Free PM & PdM Excel Planner for Industrial Maintenance

Plan, schedule, and track preventive maintenance — no software required.

What You Get

- ✔ Annual PM schedule

- ✔ Calendar-based planning

- ✔ PM & PdM tracking

- ✔ Easy Excel format

- ✔ Ready to use instantly

Who Is This For

- Maintenance Engineers

- Plant Managers

- Factory Owners

- Automation & Electrical Teams

Why PLC Automation

PLC Automation specializes in industrial automation, PLC systems, and maintenance solutions. This planner is built from real maintenance experience, not theory.