How Many Critical Automation Spares Should You Keep in Stock

- by PLC

- Jan 10, 2026

Critical Automation Spares Planning Guide

A Smarter Approach to Reducing Downtime, Risk, and Cost

In modern industrial environments, unplanned downtime is no longer just a maintenance issue, it is a business risk. Whether you operate in manufacturing, utilities, oil & gas, or process industries, the availability of critical automation spares can determine whether production continues or comes to a costly halt.

Yet many organizations still ask the same question:

How many critical spares should we really keep in stock?

The answer lies in data-driven spare parts planning, not guesswork. Below is a proven methodology used by high-performing plants worldwide, adapted specifically for PLCs, drives, and industrial automation components.

Why Critical Spare Planning Matters

Industry Facts

- Unplanned downtime costs manufacturers $50,000–$250,000 per hour on average

- Over 70% of downtime events are extended due to spare parts unavailability

- Many automation spares often face long lead times (12–26 weeks) due to obsolescence

Keeping the right automation spares, not excessive inventory, protects uptime while preserving working capital..

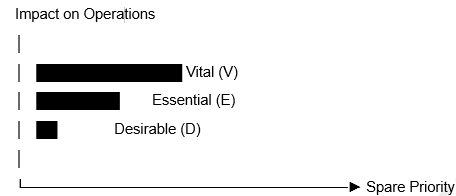

Step 1: Identify Truly Critical Automation Spares (VED Analysis)

A VED (Vital, Essential, Desirable) assessment helps prioritize inventory investment based on operational impact.

VED Criticality Chart

Automation Examples

| Category | Impact on Operations | Typical Automation Spares |

|---|---|---|

| Vital (V) | Production stops immediately | PLC CPUs, Power Supplies, Drives, Safety PLCs |

| Essential (E) | Reduced or degraded performance | I/O Modules, HMIs, Sensors |

| Desirable (D) | Minimal disruption | Cables, Indicator Lamps, Accessories |

Industry Insight:

- Only 15–20% of automation spares usually account for over 80% of downtime risk.

Step 2: Collect the Right Data (Not Just Part Numbers)

To accurately determine stock levels accurately, each critical automation spare should be evaluated using key operational data:

- Annual Usage (D): How often the part fails or is replaced

- Lead Time (LT): Manufacturing + shipping + customs + supplier delays

- Cost of Downtime: Lost production, penalties, safety risks

- MTBF (Mean Time Between Failures): Reliability indicator

- Target Service Level (Z): Availability goal (e.g., 95%, 99%)

Step 3: Use Proven Inventory Formulas (Not Estimates)

Reorder Level (ROL) Calculation

When should you place a new order?

ROL = (Average Daily Usage × Lead Time) + Safety Stock

This ensures replenishment arrives before inventory is exhausted.

Safety Stock (SS) Calculation

1. Statistical Method (Best Practice for Automation Spares)

Safety Stock = Z × σD × √(Lead Time)

- Z = service level factor (e.g., 2.33 for 99%)

- σD = demand variability

✔ Ideal for parts with unpredictable failures

✔ Reduces emergency purchases and airfreight costs

2. Basic Method (Conservative & Simple)

Safety Stock = (Max Daily Usage × Max Lead Time) – (Avg Daily Usage × Avg Lead Time)

- ✔ Useful when historical data is limited

Step 4: How Many Automation Spares Should You Actually Keep?

Industry-Proven Guidelines

| Spare Type | Recommended Stock |

|---|---|

| PLC CPU / Drive | 1 installed + 1 spare |

| Obsolete Parts | ≥ 1 spare (or lifetime buy) |

| Common I/O Modules | Shared spares across systems |

| Low-Impact Items | Order on demand |

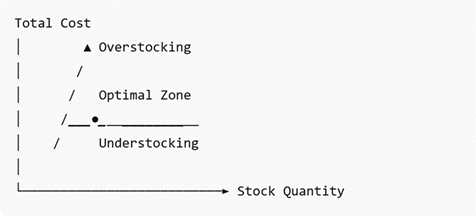

Risk vs Cost Curve

Industry Practice:

- The goal is not maximum inventory, but maximum uptime per dollar invested..

Step 5: Use Technology to Stay Ahead

Leading organizations integrate automation spare parts planning into a CMMS or EAM system, enabling:

- Automated reorder alerts

- Asset-to-spare linkage

- Failure trend analysis

- Obsolescence tracking

Results:

Companies using CMMS-driven spare strategies reduce:

- Emergency purchases reduced by 20–30%

- Downtime related to missing parts reduced by up to 40%

Step 6: Review, Optimize, and Obsolescence-Proof

Automation environments evolve rapidly. Regular reviews ensure spares strategies remain aligned with operational reality.

Best Practices

- Annual spare criticality review

- Quarterly inventory audits

- Supplier lead-time monitoring

- Obsolescence risk assessment

Final Takeaway: Smart Spares = Competitive Advantage

Keeping the right number of critical automation spares is not a cost, it is insurance against downtime, safety incidents, and lost revenue.

By combining:

- ✔ Criticality analysis

- ✔ Data-driven inventory formulas

- ✔ Modern CMMS / EAM systems

- ✔ Reliable automation spare partners

...organizations achieve higher availability, lower risk, and better ROI.

Ready to Reduce Downtime from Automation Spare Shortages?

Many plants carry too much of the wrong inventory, and too little of what truly matters.

If you’re unsure whether your current automation spare strategy is:

- Increasing downtime risk

- Tying up unnecessary working capital

- Exposed to obsolescence or long lead times

We can help.

Free Critical Automation Spares Review

Our specialists will:

✔ Identify high-risk PLC, drive, and automation components

✔ Assess spare criticality, lead times, and obsolescence exposure

✔ Recommend optimized stock levels based on real operational data

✔ Highlight quick wins to reduce downtime and emergency purchases

👉 Request your free automation spares audit

(No obligation. Practical recommendations you can act on immediately.)