Understanding MES with A Key Investment for Manufacturers

- by PLC

- Aug 27, 2023

In the ever-evolving landscape of manufacturing, staying competitive requires adopting advanced technologies that enhance efficiency, productivity, and overall operations. Manufacturing Execution Systems (MES) have emerged as a crucial tool for achieving these objectives. In this blog post, we will delve into the concept of MES, its significance, and the reasons why manufacturers should consider investing in it.

What is MES?

Manufacturing Execution Systems (MES) are integrated software solutions designed to streamline and optimize the production process within a manufacturing facility. MES acts as a bridge between enterprise resource planning (ERP) systems and the shop floor, ensuring effective communication and coordination between different stages of production. MES software provides real-time insights, data collection, and analysis, enabling manufacturers to make informed decisions that lead to improved operational efficiency and quality.

The Significance of MES for Manufacturers

- Real-time Visibility and Data: MES provides manufacturers with real-time visibility into their production processes. This means that managers can monitor operations as they happen, identify bottlenecks, and address issues promptly. Accurate, up-to-date data empowers decision-makers to optimize production schedules, allocate resources effectively, and respond swiftly to changes in demand or supply chain disruptions.

- Enhanced Production Control: MES enables precise control over the manufacturing process. It ensures that the right materials are used at the right time, reducing waste and errors. Manufacturers can enforce quality control measures and standard operating procedures (SOPs), resulting in consistent product quality and regulatory compliance.

- Efficient Resource Utilization: Investing in MES leads to improved resource utilization. Manufacturers can better manage labor, equipment, and materials, optimizing their usage to minimize downtime and maximize output. This efficiency directly impacts the bottom line by reducing operational costs.

- Quality Assurance: MES contributes to enhanced product quality by facilitating real-time monitoring and data collection. Manufacturers can identify defects or deviations from quality standards early in the process, reducing the likelihood of producing faulty products and minimizing rework.

Traceability and Compliance: Regulatory compliance and product traceability are critical in industries such as pharmaceuticals, aerospace, and food. MES systems track and document every step of the manufacturing process, ensuring that products can be traced back to their origins if issues arise. This feature is invaluable in maintaining consumer trust and meeting industry regulations.

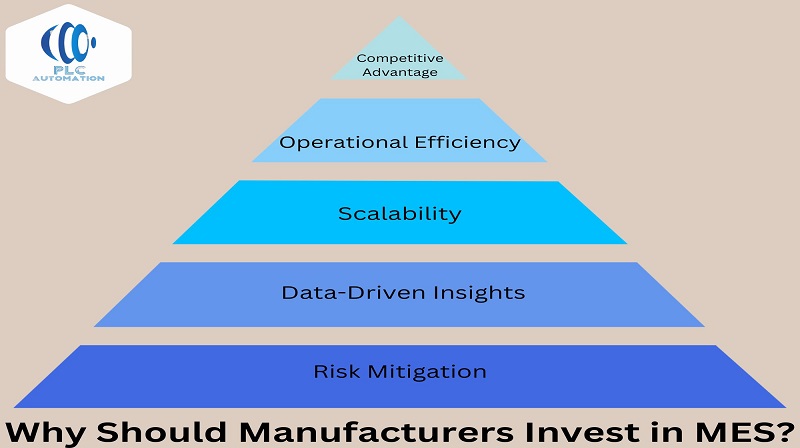

Why Should Manufacturers Invest in MES?

- Competitive Advantage: In today's fast-paced manufacturing landscape, companies that embrace technological advancements gain a competitive edge. MES enables manufacturers to respond swiftly to market demands, produce high-quality products consistently, and adapt to changing customer preferences.

- Operational Efficiency: MES optimizes production processes, reduces waste, and enhances resource utilization. This translates to improved operational efficiency, lower costs, and higher profit margins.

- Scalability: As manufacturers expand their operations, scaling up production can become complex. MES systems are designed to accommodate growth, making it easier to replicate successful processes and systems across multiple sites or lines.

- Data-Driven Insights: MES provides valuable insights through data analytics, helping manufacturers identify trends, patterns, and areas for improvement. Informed decision-making based on data leads to better outcomes and more agile operations.

- Risk Mitigation: By ensuring regulatory compliance and product traceability, MES mitigates the risks associated with recalls, defects, and non-compliance. This safeguards brand reputation and minimizes financial losses.

Manufacturing Execution Systems (MES) have evolved into indispensable tools for modern manufacturers seeking to thrive in a competitive environment. The benefits of real-time visibility, production control, resource utilization, quality assurance, and compliance are compelling reasons to invest in MES. Manufacturers who embrace MES position themselves for increased operational efficiency, heightened competitiveness, and sustainable growth in the dynamic world of manufacturing.